|

Technova Ball Valves

Typical Service Applications:

Chemical CPI Chemical CPI - Petro-Chemical

- Bio-Technical

- Pharmaceutical Industry

- Pulp and Paper

- Food Processing

- Paint and Pigments

- Fertilizers

- Textile Industry

- Mining and Steel

- Water Treatment

- ...

Main Features:

- heavy-duty, robust contstruction

- maintenance-free

- body halves friction locked (metal to metal)

- Bubble-tight shut-off thrught the full pressure and temperature range

- one-piece ball/shaft, PFA-encapsulated

- Zero stem leakage provided by an innovative stem sealing mechanism

- Consistent low operating torque

- ball seats of virgin PTFE

- Maximum flow rates at lowest pressure drops

- Integrated ISO top flange for standard actuators

- Flanges according to DIN PN 10/16 respectively ANSI 150lbs for installation into existing piping systems

Modular Design:

Ball Valves SBV Series are available as DIN- or ANSI- valves, with handlever for manual quarter turn operation as per standard or with bare shaft for easy installation of actuator units. A padlock on the handlever on ISO top flange, with a safety lock is also available. The sturdy design bodies are made of cast steel 1.0619 (WCB A216) RAL 5005 signal-blue epoxy-coated or compl. of SS316 casting 1.4408 (CF-8M), with resistant linings such as PFA or PFA-AS (conductive)

Technical Data:

- Nominal Sizes: DN15-DN100 respectively 1/2" - 4",6" reduction port

- Flanges according to DIN PN10/16 respectively ANSI 150lbs

- F/F according to EN 558-1 range 1 respectively ASME B16.10

- Bodies: cast steel ASTM A216 WCB or CF-8M, ISO flange

- Linings: PFA, PFA-AS(conductive)

- Balls: PFA, PFA-AS, ETFE, SS Duplex, Titanium Gr.2

- Ball seats: PTFE, PTFE-AS (conductive)

Operating Conditions (depending on material Selection)

- Pressure: 1 mbar (0.014 psi) up to 16 bar (232 psi)

- Temperature: -40C (-40F) up to +200C (+392F)

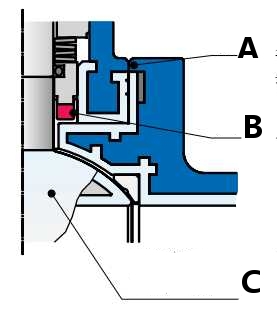

Dynamic Sealing System Standard:

|

- Body halves with metal-to-metal joint

- Pre-loaded, dynamic shaft seal. Resilient inserts made of VMQ (Silicone) or FPM (Viton) provide a uniform pressure for positive tight shut-off

- One-piece ball/shaft, SS Duplex (1.4462) cores with encapsulations made of PFA, PFA-AS, ETFE or solid balls made of SS Duplex, Titanium Gr.2

|

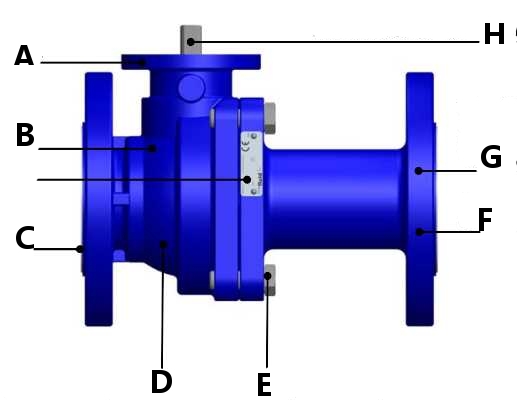

Construction Of The Valve:

|

- Mounting Top flange ISO 5211

- Marking according to EN 19

- Name Plate SS304

- One-piece ball/shaft, PFA-encapsulated, thickness minimum 3mm

- Body Bolts SS304, A2-70

- Flange standard according EN 1092 or ASME B16.5

- Two-piece body made of cast steel 1.0619 (WCB), RAL 5005 signal-blue coated or stainless steel casting 1.4408 (CF-8M)

- Double Shaft according to EN 12116

|

Mounting Options:

|

- Limit switch box

- Filter Regulator

- Solenoid valve

- Manual override

- Locking Handle

- N0AMUR bracket

- Position indicator

- SPA Pneumatic actuator

- Bare shaft DD

- Manual gearbox

- ISO mounting kit

- Silencer

- Throttling valve & Silencer

- El. Pneumatic positioner

|

Options:

- CS - Ball with large opening (C-type cross-section), to prevent any pressure build-up or residues trapped inside the closed ball, for full drainage

- Vp - V-port balls for control/throttling applications, with various contours. Bals gen.: one-piece design, blow-out proof

Testing & Marking:

- pressure and tightness testing according to EN 12266-1, leakage rate A, and spark testing at 36 kV to assure lining integrity.

- Marking of valves on body and name plate according to EN 19

- material resp. test certificate acc. to EN 10204-3.1

For more information about Technova valve products, contact

|