|

Technova Butterfly Valves

Main Features:

Heavy-duty, compact construction Heavy-duty, compact construction - maintenance-free

- Bubble-tight shut-off throughout the full pressure and temperature range

- wide selection of high-quality liner and disc materials for economical valve performance

- Unique shaft sealing arrangement assures maintenance-free operation at automated processes and high operating prerssures, with optimized and reinforced liner shape

- One-piece disk/shaft for hysteresis-free flow control, with polished sealing surface, leading to low torque values

- Wide and chambered flange sealing surface does not require additional flange gaskets

- Flange drilling according to DIN PN10/16 resp. ANSI 150lbs for installation into existing piping systems

Typcial Service Applications:

Chemical CPI Chemical CPI - Petro-Chemical

- Bio-Technical

- Pharmaceutical Industry

- Semi-Conductors

- Pulp and paper

- Food processing

- Paint and Pigments

- Textile Industry

- Mining and Steel

- Steel / Metal processing

- Desalination

- Chlor Alkali

- Water Treatment

- Detergents, Oils and Fatty Acids

Technical Data:

- Nominal Sizes: DN25 - DN1000 respectively 1" - 42"

- Flanges according to DIN PN10/16 resp. ANSI 150lbs

- F/F acc. to EN 558-1 range 20 respectively ASME B15.10

- Bodies: Cast steel ASTM A216 WCB, CF-8M, ISO flange

- Liners: PTFE, PTFE-AS(conductive), UHMWPE

- Discs: PFA, PFA-AS, PVDF- or ETFE-encapsulated, solid made of SS Duplex, Titanium Gr.2, Hastelloy

- Elastomer backings: VMQ (Silicone), FPM (Viton), EPDM

Operating Conditions:

(depending on material selection)

- Pressure 1mbar (0.14psi) up to 16 bar (232 psi)

- Temperature -40C (-40F) up to +220C (+428F)

Dynamic Sealing System (standard):

- Shaft sealing Pre-loaded, dynamic shaft sealing arrangement

- the pressure ring transfers the bellevill-spring action and elastomer compression force onto liner and disc hub, providing a bubble-tight shaft sealing mechanism for upper and lower section.

- Elastomer Backings provide a resilient and uniform pressure onto sealing surface for positive tight shut-off, available in various qualities

- One-piece disc/shaft, SS Duplex (1.4462) cores with encapsulations made of PFA, PFA-AS, PVDF, ETFE or solid discs made of SS Duplex, Titanium Gr.2, Hastelloy C etc.

Testing / Marking:

- Pressure and tightness testing acc. to prEN 12266-1, leakage rate A, and sparking at 35 kV to assure lining integrity. Marking on valves on body and name plate according to EN 19.

- Material respectively test certificate according EN 10204-3.1B

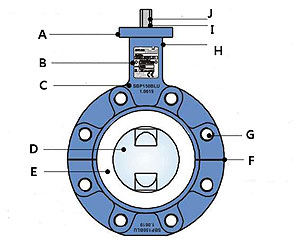

Valve Construction Diagram

|

- Mounting Top flange according to EN ISO 5211, including O-ring

- Name Plage 1.4301 (SS304)

- Marking according EN 19

- One-piece disc/shaft, solid or encapsulated minimum 2.5mm

- Liners made of PTFE, PTFE-T or PTFE-AS (anti-static), thickness minimum 3mm, with VMQ or FPM backing

- Body Bolts made of 1.4301, A2-70 (SS304)

- Flange Standard according to EN 1092 or ASME B16.5

- Body made of cast steel 1.0619 (WCB), powder-coated RAL 5005 signal-blue or stainless steel casing 1.4408 (CF-8M)

- Rated Breaking Point

- Double-D shaft according to EN 12116

|

|

|

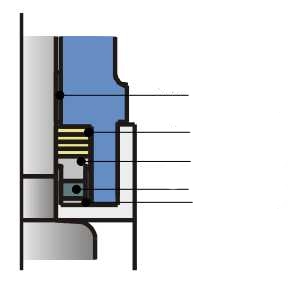

Dynamic Shaft Seal:

|

- Triple shaft bearning

- Belleville springs

- Pressure ring

- Elastomer insert

- Guide Ring

|

Mounting Options:

|

- Limit switch box

- Filter Regulator

- Solenoid valve

- Manual override

- Locking Handle

- N0AMUR bracket

- Position indicator

- SPA Pneumatic actuator

- Bare shaft DD

- Manual gearbox

- ISO mounting kit

- Silencer

- Throttling valve & Silencer

- El. Pneumatic positioner

|

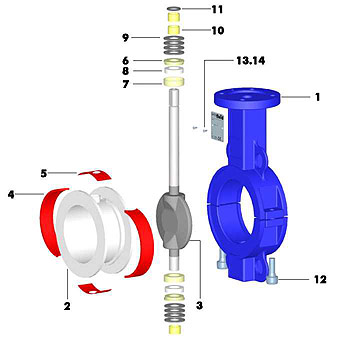

Valve Wafer Parts List:

|

- Body two-piece, RAL 5005, WCB

- Liner, PTFE

- Disc Encapsulated, Duplex/PFA

- Elastomer, VMQ

- Elastomer Pad, VMQ

- Pressure Ring, Carbon Steel

- Guide Ring, C.Steel

- Elastomer Insert, VMQ

- Belleville Spring, Spring Steel

- Bearing DU, C.Steel/PTFE

- O-Ring top, FPM

- Socked Head Cap Screw, A2-70

- Name Plage 42x14 CE, A2

- Hammer Screw 2.49x4.76, A2

|

For more information about Technova valve products, contact

|